PCB Test: Enhancing Supply Chain Efficiency

PCB Test: Enhancing Supply Chain Efficiency

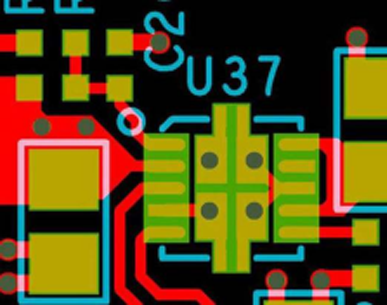

In today’s rapidly evolving technological landscape, the demand for efficient and reliable printed circuit boards (PCBs) has never been higher. pcb testing plays a crucial role in ensuring the quality and functionality of these essential components, enabling businesses to meet customer expectations and maintain a competitive edge.

The Importance of PCB Testing

pcb testing is an integral part of the manufacturing process as it helps identify any defects or faults that may have occurred during production. By subjecting PCBs to rigorous testing procedures, manufacturers can ensure that only high-quality products reach the market. This not only minimizes the risk of product failures but also enhances customer satisfaction and brand reputation.

Furthermore, PCB testing enables early detection of potential issues such as short circuits, open circuits, faulty components, or incorrect connections. Identifying these problems at an early stage allows for timely corrections and prevents costly rework or recalls further down the supply chain.

The Advancements in PCB Testing

With advancements in technology, PCB testing methods have become more sophisticated and efficient. Automated test equipment (ATE) systems now offer comprehensive analysis capabilities that enable faster and more accurate fault detection. These systems utilize various techniques such as boundary scan tests, functional tests, in-circuit tests (ICT), flying probe tests (FPT), and automated optical inspection (AOI).

Beyond traditional electrical testing methods, newer approaches like X-ray inspection are gaining popularity due to their ability to detect hidden defects within complex multilayered boards. Additionally, advancements in artificial intelligence (AI) algorithms are being integrated into test equipment software to enhance fault diagnosis accuracy while reducing human error.

JinHua: Revolutionizing Supply Chain Efficiency

JinHua is one company at the forefront of revolutionizing supply chain efficiency in PCB testing. Their state-of-the-art facilities and cutting-edge technologies enable them to offer comprehensive testing solutions that meet the highest industry standards.

By leveraging advanced ATE systems, JinHua ensures efficient and accurate fault detection, significantly reducing production time and costs. Their commitment to continuous improvement and innovation has enabled them to streamline their processes, resulting in faster turnaround times without compromising on quality.

JinHua’s strategic location also plays a vital role in enhancing supply chain efficiency. Situated near major manufacturing hubs, they can quickly receive raw materials and deliver finished products within shorter lead times. This proximity reduces transportation costs while ensuring timely delivery to customers worldwide.

Conclusion

In conclusion, PCB testing is an essential aspect of ensuring supply chain efficiency in today’s technology-driven world. By implementing robust testing procedures, manufacturers can identify defects early on, minimize risks, enhance customer satisfaction, and maintain a competitive edge. Companies like JinHua exemplify how advancements in PCB testing technologies combined with strategic operational practices can optimize supply chain efficiency for businesses globally.